Airotech Minerals

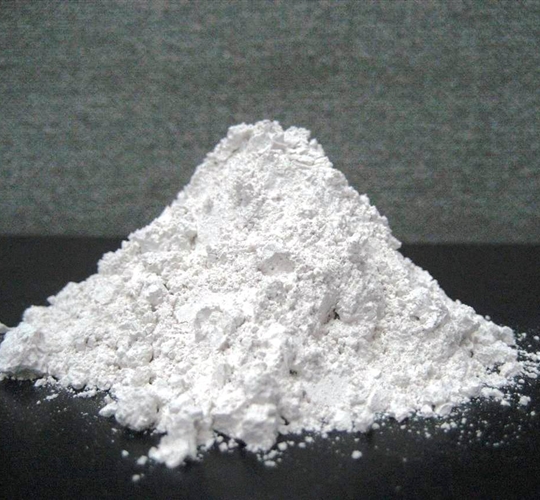

Dolomite was named for the French mineralogist Deodat de Dolomieu. The mineral dolomite is commonly found in deposits of a sedimentary rock called dolostone. There are two types of materials often called dolomite, a true chemically uniform calcium magnesium carbonate with the chemical formula CaMg(CO3)2, and a dolomite limestone, which is just an irregular mixture of calcium and magnesium carbonates. Dolomite is believed to have formed by the replacement of some of the calcium in a calcium carbonate limestone deposit with magnesium, while the sediment was undergoing lithification, being converted from layers of dead clam and other sea animal shells into crystallized calcite or calcium carbonate. The resultant dolomite mineral, CaMg(CO3)2 is a true double salt. The calcium and magnesium ions in dolomite exist in separate layers in the crystal matrix. Dolomite has a calcium layer, then a carbonate layer, then a magnesium layer then a carbonate layer, and so on.

Dolomite is available in different particle size ranges: 2.5, 5, 25, 50, 150 and 600, also available as per customer’s specification. Dolomite is harder and denser than the calcite form of calcium carbonate or limestone and is more chemically inert and more impervious to acid attack.

Send EnquiryTECHNICAL SPECIFICATION

| CaCO3 | 55 +/ -1 |

| MgCO3 | 44 +/ -1 |

| SiO2 | 0.2% |

| Fe2O3 | 0.15% |

| Ai2O3 | 0.45% |

| l.O.I | 41% |

| Pack Size | 50KG |

Applications

Dolomite Powder for Construction Material

As a construction material, Dolomite is crushed and sized for use as a road base material, an aggregate in concrete and asphalt, railroad ballast, rip-rap (armour shorelines, streambeds, bridge abutments, pilings and other shoreline structures against scour and water erosion), or fill. Dolomite is chosen as a construction material due to its increased hardness and density. Asphalt and concrete applications prefer dolomite as filler because of its higher strength and hardness.

Dolomite Powder for Iron and Steel Industry

In the iron and steel industry, the main uses of dolomite are (i) as a fluxing material (ii) for the protection of refractory lining, and (iii) as a refractory raw material. Dolomite in the iron and steel industry is normally used in three forms. These are (i) raw dolomite which is also the natural form of dolomite, (ii) calcined dolomite, and (iii) sintered dolomite. When dolomite is used as a fluxing material then it is used as either raw dolomite or calcined dolomite. When dolomite is used for the protection of refractories, it is used in calcined form and when dolomite is being used as a refractory raw material, it is used in the form of sintered dolomite.

Dolomite Powder for Chemical Industry

In the chemical industry, dolomite is used as a source of MgO. In agriculture, dolomite is used as a soil conditioner and as a feed additive for livestock. Dolomite has been used as a minor source of magnesium, but today most magnesium is produced from other sources. Calcined dolomite is also used as a catalyst for the destruction of tar in the gasification of biomass at high temperatures.

Dolomite Powder for Agriculture

Dolomite is relatively soft and can easily be crushed to soft powder. Dolomite powder is used in agriculture to reduce soil acidity and also to adjust magnesium deficiency. Magnesium is an important plant nutrient. Dolomite powder is used as filler in various products like detergent, paints, rubbers, agriculture products, animal feed, putty, and other adhesives and sealants,. It is used in the manufacture of plastics as well as ceramic tiles. Dolomite is finely ground to precise size specifications. Pure white (high brightness) filler grades are preferred but these are rare.

Dolomite Powder for Glass Industry

Another important use of Dolomite is in Glassmaking Industry. Most commercial glasses consist essentially of silica together with soda (Na2O) and lime (CaO), the lime being partly replaced by magnesia for the same purpose. Lime is introduced into the glass melt as limestone and magnesia by adding dolomite. However, in flat gas industry, most lime is introduced with the dolomite and only a small amount of limestone is used to balance the CaO/MgO ratio. Lime and magnesia improve the durability of glass but magnesia also inhibits the devitrification process, which is particularly important for the manufacture of flat glass.

Dolomite Powder for Container Glass

Dolomite is also used in container glass. A critical property of the glassmaking grade of dolomite is the iron content, since it is considered a serious impurity in the manufacture of colourless glasses. Very low content of Fe2O3 is needed for the manufacture of colourless glass containers and, sometimes, low iron flat glasses. In contrast to silica sand, mineral processing cannot effectively lower the iron content of dolomite.